-

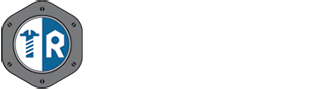

Tapered Section Rings

Rotor Clip Tapered Section Rings best in the industry.Tapered Section Retaining Rings are the most common type of retaining ring in use today. They are manufactured by stamping rolled steel into the finished shape, or by coiling rectangular section wire and then cutting out the taper and lug holes. The tapered section gives these rings the flexibility to be installed using a retaining ring plier. Also, the heavy cross section of these retaining rings allow them to have high thrust load capacities -

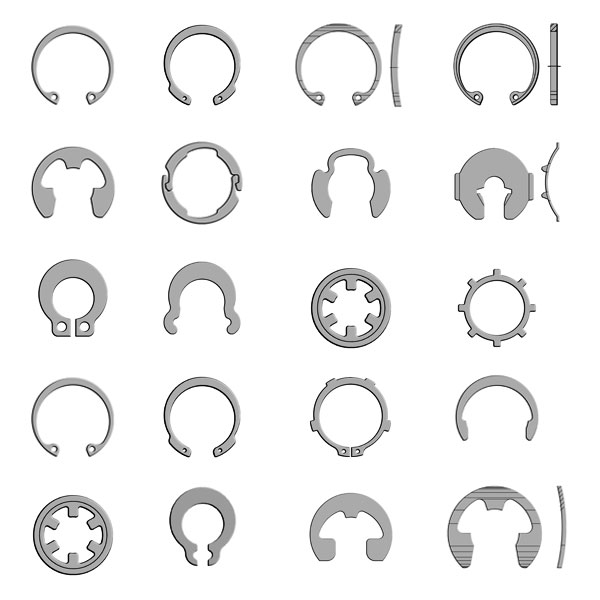

Constant Section Rings

Rotor Clip Constant Section Retaining Rings are manufactured by coiling heavy section wire. This process yields a retaining ring that supports high thrust loads. Plier type tools are available to ease installation on some series of rings. Many material and finish choices are available and custom designs typically do not require any custom tooling, so specials are very economical to produce. -

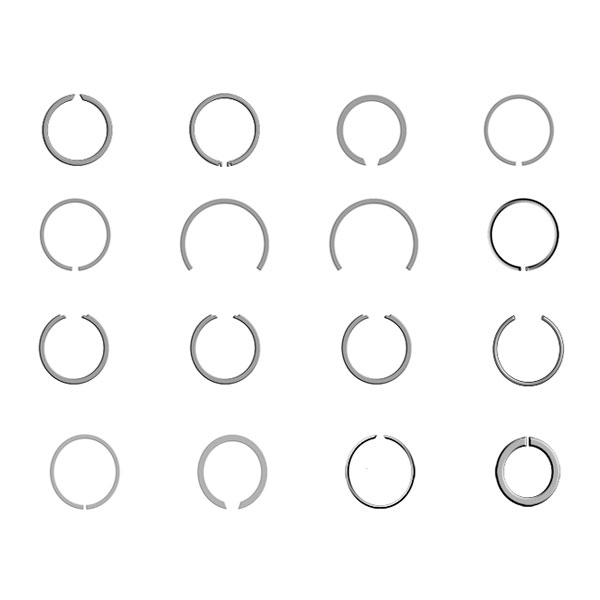

Spiral Rings

Rotor Clip Spiral Wound Retaining Rings are manufactured by coiling thin section flat wire. This process yields a retaining that supports medium to high thrust loads and still remains flexible enough to be installed by hand. Spiral rings offer engineers more clearance than rings which have removal lugs, so if clearance diameter is a concern, then a spiral ring should fit the bill. Most spiral rings are designed with multiple turns, producting a full 360 degree retaining shoulder. Many material and finish choices are available and custom designs typically do not require any custom tooling, so specials are very economical to produce. -

Wave Springs

When compared with typical coil springs, wave springs have equal performance with about half of the overall free height. The space savings leads to smaller, less expensive assemblies. Rotor Clip manufactre Wave springs in many styles and materials . -

Hose Clamps

Rotor Clamp, Inc. produces a line of self-compensating hose clamps for low-pressure applications in single wire, double wire and constant tension band (CTB) configurations, including light band and narrow band clamps. These clamps expand and contract with the hose in response to temperature changes in the application. They cannot be over or under tightened, and are installed and removed easily using either manual or pneumatic tools. -

Tools

Once a part is chosen, it must be installed, utilized and possibly removed. To support many fastener designs, which are engineered with usability in mind, Rotor Clip provides a full line of installation and removal tools that makes intallation easy,precise and economical.